The full story of our epic Bahrain Bentley engine rebuild

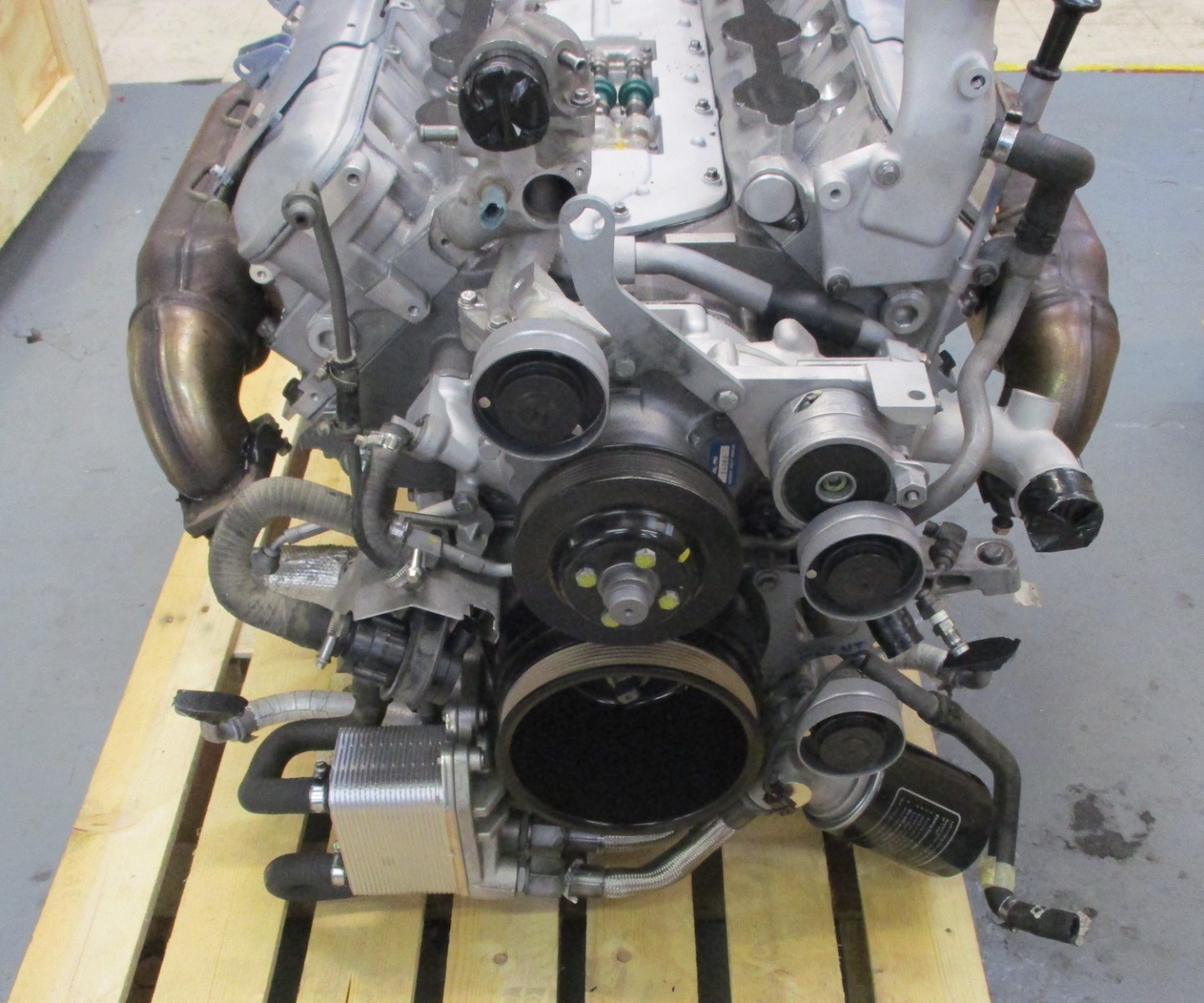

As you might have read in the news, we at Flying Spares have been celebrating the successful completion of our toughest ever reconditioning project – rebuilding an RS60 V8 engine for a rare Bentley Brooklands Coupé.

https://www.express.co.uk/life-style/cars/1739986/Bentley-coupe-royal-repair-motor-Flying-Spares

It was only after we’d done it we found out the car belongs to a senior member of the Bahrain royal family. Proof, if any were needed, that we treat every customer like royalty… but of course you already know that!

The epic story started innocently enough. Salesman Adam took a call from a Bentley dealer in Bahrain asking if we could fix a damaged engine from a two-door 2009 Bentley Brookland.

No problem. We get calls like that quite often. Sure, we’ll take a look. Even if Bentley consider it beyond repair? Yeah, we like a challenge.

Well, some weeks later a stack of boxes arrived at our workshop in Market Bosworth. They contained not only the engine but the gearbox, turbos, wiring loom and all kinds of ancillaries.

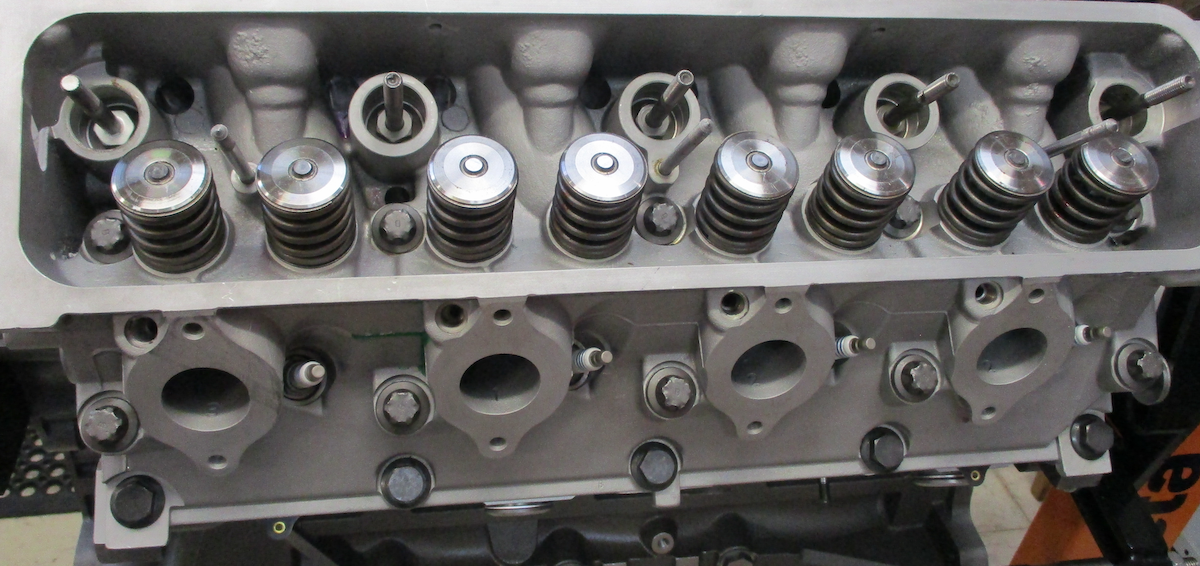

It was a high-tech jigsaw puzzle, but we soon pieced it together and identified the fault. The camshaft follower (a hydraulic tappet) was shattered, so it had rotated around the cam causing a right mess. The whole engine had to be stripped down.

13 Mar 2023

13 Mar 2023