It’s almost one year to the day since Flying Spares began one of our most in-depth product tests to date.

Our development team had been working with a reputable brake disc manufacturer that carried R90 approvals and had just introduced a set of Bentley GT, GTC, and Flying Spur front brake discs to their portfolio. Naturally, we were interested. Our goal is to supply high-quality products that offer value for money.

Immediately we hit a slight bump. The discs listed were set up for directional cooling, the original discs fitted from the factory are not. For those unfamiliar, directional cooling improves internal airflow by means of directional vents within the disc, reducing the chance of brake fade when subjected to extreme load. For that reason, the brake discs are left and right-handed. This setup tends to be used on high-performance vehicles.

After a lot of discussion and deliberation, we decided to bring in samples and begin testing. The first step of the process involves our quality control department which tests and checks product specifications, dimensions, and composition. Manufacturing parts involves precision machining and specific heat treatments, often to tiny tolerances. Sometimes a product may have been rough machined, or metals that haven’t been tempered correctly. The important thing is to identify issues early. Malcolm our chief engineer immediately got to work making sure everything ticked all the boxes before the discs were passed over to our Technical Services Department (TSD) to be fitted to the test and development Bentley GT where they would get a proper workout on the road.

Understandably the GT is popular with the Flying Spares team and not a day goes by without someone using it, this way the discs would be subject to a multitude of driving styles ranging from ‘Driving Miss Daisy’ all the way up to ‘The Fast and the Furious’ (within speed limits). During this time, we would check for brake fade, wear, distortion, comfort, and noise. The discs would be checked regularly with the car on the ramp.

After 11 months and thousands of miles on the road, everything was great. no issues at all, but with the discs being a safety-critical item, we knew we had to go further and push them harder, something we couldn’t achieve legally on the British roads.

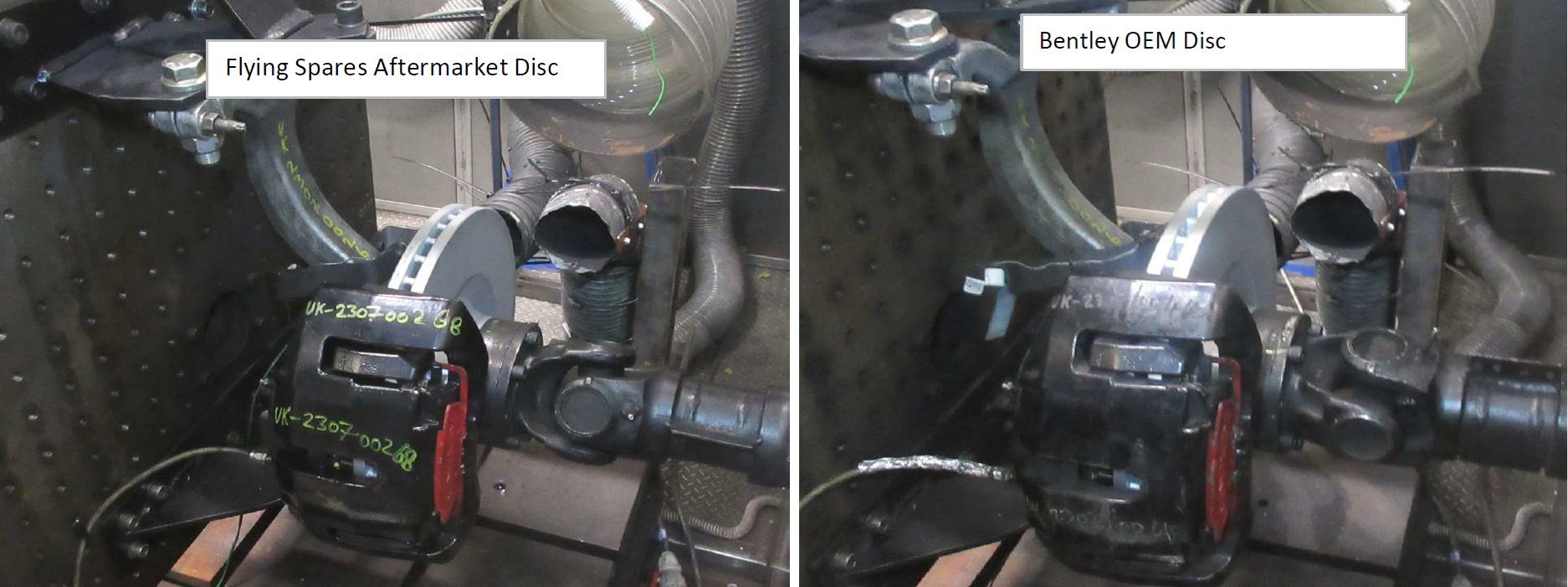

The only way we could really put the discs through extreme conditions was at one of the UK’s leading brake test and development centres. The tests consisted of recurring brake applications until thermal fatigue was reached, slowing from 206mph to 12mph with a simulated weight matching that of a Bentley Flying Spur. The discs were subject to temperatures reaching 780c and proved to be consistently 5% cooler than the genuine discs (these were tested at the same time) and achieved a higher number of cycles (10%) until thermal fatigue was reached. Proving that the directional fins on our disc improved the braking performance and cooling properties compared to the genuine discs.

We are delighted to officially announce that these discs have passed all tests with flying colours and are available to purchase for Bentley GT, GTC and Flying Spur. The discs are available to purchase as pairs only and we would only recommend changing discs as a pair for safety reasons.

22 Aug 2023

22 Aug 2023